- Tiendas

- Konto erstellen

- Startseite

- Elektrische Ausrüstung

- Anschluss- und Befestigungsmaterial

- Automaten und Displays

- Befehl und Signalisierung

- Dienstleistungen

- Direkt- und Stern-Dreieck-Starter, Softstarter

- Elektrische Kabel und Schläuche

- Elektromagnetische und Halbleiterrelais

- Endschaltungen - positionsdetektoren - elektrische Pedale - Sensoren

- Erdungselemente

- Flexibler Schlauch

- Frequenzumrichter

- Hebezeuge - Brückenkräne - Hebezeuge

- Kabelverschraubungen und elektrische Armaturen

- Kondensatoren

- Magnetothermische und Differentialschutzschalter

- Messgeräte

- Metallgehäuse und Schränke

- Motorschutz Motorschutzschalter Motorschutz

- Schalter - Trennschalter

- Schütze und Mini-Schütze

- Sicherungen und Sicherungshalter

- Steuer- und Schutzrelais, Thermostate, Temperaturfühler

- Steuer- und Schutztafeln bereits verdrahtet

- Stromversorgungen

- Thermische Strahler

- Thermoplastische und faserverstärkte Schränke und Gehäuse

- Thermorelais

- Timer - Schalter und Timer-Programmiergeräte

- Transformatoren und Spartransformatoren, Spannungsstabilisatoren, USV

- Vakuumschalter, Druckschalter und Durchflussmesser

- Wandleuchten und Beleuchtungselemente

- Elektrische Motoren

- Anlasser für Elektromotoren

- Dreiphasige Elektromotoren 230/400V und 400/690V IE1, IE2 und IE3

- Einphasige Elektromotoren mit mittlerem und hohem Anlaufmoment.

- Elektromotoren mit Bremse

- Frequenzumrichter

- Motoren für Betonmischer

- Riemenscheiben zur Kraftübertragung für Elektromotoren

- Schwimmbad-Pumpen

- Spannsockel und Führungen für Elektromotoren

- Taper Lock Taper-Buchsen für Riemenscheiben

- Treibriemen für Motoren

- Vibrationsmotoren

- Zubehör und Ersatzteile für Elektromotoren

- Getriebe

- Pneumatisches Material

- Druckluftfiltrations- und -aufbereitungsanlagen

- Druckschalter, Vakuumschalter und Durchflussmesser

- Durchflussregler, pneumatische Anschlüsse

- Elektromagnetische Ventile

- Ersatzteile und Zubehör für Kompressoren

- Hydraulische Stoßdämpfer

- Pneumatische Druckverstärker (Booster) - Luftbehälter

- Pneumatische und Zubehör

- Pneumatische Ventile

- Pneumatische Zylinder

- Ventile mit pneumatischen Antrieben

- Verschiedene Materialien Pneumatik

- Wasserfiltrations- und -aufbereitungsanlagen

- Druckluftnetze

- Absperrventile für Druckluftanlagen

- Elemente für Fallrohre und Abzweige für Druckluftanlagen

- Ergänzungen für Druckluftnetze

- Ersatzteile und Zubehör für Kompressoren

- Rohr für Druckluftinstallationen

- Schnellstecker und Anschlüsse für Druckluftinstallationen

- Steckdosen

- Union für Druckluftinstallationen

- Zubehör und Verbindungselemente für Druckluftsysteme

- Zubehör und Werkzeuge

- Lager

- Mechanische Ausrüstung

- Aluminiumprofile

- Elastische Präzisionskupplungen

- Gleitlager aus Blech und Sinterbronze

- Gleitschlitten und Führungen

- Kraftübertragungsriemen

- Kugelgelenke, Stangenköpfe und Gabelköpfe

- Muttern, Scheiben und Befestigungshülsen

- Öldichtungen

- Präzisionsspindeln, Muttern und Halterungen

- Riemenscheiben für die Kraftübertragung

- Ritzel, Ketten, Räder, Taper-Lock-Buchsen und Scheiben

- Stützen und Spanner mit Lagern

- Zahnräder und Zahnstangen

- Hardware

- Zone Outlet

Drehstrom-Vibrationsmotor 0,3kW 3000 rpm 230/400V B3 Beine

249,06 € ohne Steuer.

Dreiphasiger elektrischer Vibrationsmotor 0,3kW (0,4CV) 230/400V 50Hz, 3000 U/min (2 Pole), B3-Flansch, Füße, Aluminiumgehäuse. Vorgesehen für verschiedene Anwendungsbereiche in unterschiedlichen Industriezweigen.

Repräsentatives Bild zur Veranschaulichung, der gelieferte Artikel entspricht den angegebenen Spezifikationen.

Vibrationsmotoren sind Elektromotoren, die über Gegengewichte oder Unwuchtmassen verfügen, die sich an beiden Enden ihrer Drehachse befinden, um Vibrationen zu erzeugen und zu übertragen. Die Rotation dieser Unwuchtmassen erzeugt eine auf die Motorwelle wirkende Fliehkraft, die wiederum in Form einer Schwingungsbewegung auf eine bestimmte Maschine oder Struktur übertragen wird.

Eigenschaften:

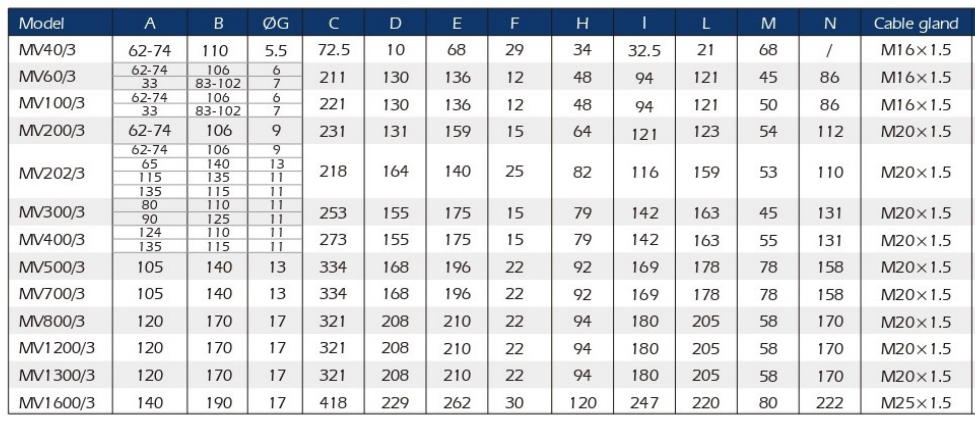

- Hersteller/Importeur: Motorseg

- Teilenummer: MV400/3

- Spannung: 230/400V 50Hz

- Anzahl der Pole: 2

- Umdrehungen: 3000 U/min

- Leistung: 0,3kW (0,4CV)

- Zentrifugalkraft: 4kN (400Kg)

- Maximaler Strom: 0,58A

- Art der Befestigung: B3 (Schenkel)

- Farbe: Orange

- Gehäusegröße: Größe 30

- Gehäusematerial: Aluminium

- Einstellbare Massen

- Isolierstoffklasse F

- Schutzart: IP65

- Gewicht: 10,2Kg

- CE-gekennzeichnet

WICHTIG: Alle Vibrationsmotoren müssen mit einem Überlast- oder Überverbrauchsschutz (Leistungsschalter oder Motorschutz) ausgestattet sein. Wenn mehrere Geräte zusammen installiert werden, muss jedes Gerät mit einem individuellen Überlastungsschutz ausgestattet sein.

Hinweis: Vergewissern Sie sich, dass das Gerät mit der richtigen Spannung und Frequenz gemäß dem Typenschild des Geräts versorgt wird. Verwenden Sie ein Kabel mit entsprechendem Querschnitt und schließen Sie es mit den entsprechenden Klemmen an die Stromversorgungsklemmen des Motors an. Schließen Sie das Erdungskabel an die entsprechende Klemme an.

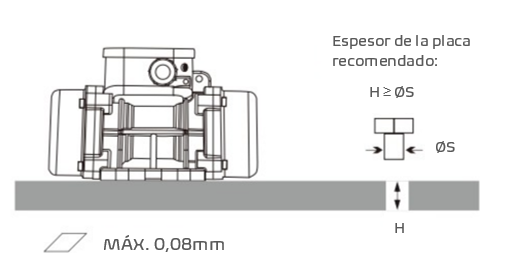

Hinweis: Die Oberfläche, auf der der Vibrationsmotor installiert wird, muss eine zulässige Toleranz von 0,08 mm aufweisen, damit die Oberflächen der Arbeitsflächen und des Geräts gleichmäßig aufeinander liegen, um innere Spannungen zu vermeiden, die zum Bruch des Sockels oder der Beine des Motors führen könnten.

Für weitere Informationen können Sie das Installationshandbuch herunterladen, indem Sie auf die Registerkarte "Anhänge" klicken.

Material für den professionellen Einsatz, Installation unter Beachtung der am Aufstellungsort geltenden Vorschriften.

Fragen

Seien Sie der Erste, der eine Frage zu diesem Produkt stellt!

Frage zum Produkt

Verantwortlicher: ADAJUSA (CONSTRUCCIONES PBR, S.L.), Zweck: Beantwortung von Informationsanfragen, Legitimität: Zustimmung des Interessenten, Empfänger: Daten werden nicht an Dritte weitergegeben, Rechte: Zugriff auf, Berichtigung und Löschung von Daten usw Rechte, wie in den zusätzlichen Informationen erläutert. (lesen)

16 andere Produkte in derselben Kategorie:

Drehstrom-Vibrationsmotor 1,3kW 1500 rpm 230/400V B3 Beine

Drehstrom-Vibrationsmotor 0,16kW 1500 rpm 230/400V B3 Beine

Einphasiger Mikro-Vibrationsmotor 0,07kW 3000 rpm 230V B3 Beine

Drehstrom-Vibrationsmotor 0,05kW 3000 rpm 230/400V B3 Beine

Drehstrom-Vibrationsmotor 0,5kW 3000 rpm 230/400V B3 Beine

Einphasiger Vibrationsmotor 0,08kW 3000 rpm 230V B3 Beine

Drehstrom-Vibrationsmotor 0,18kW 3000 rpm 230/400V B3 Reduzierte Gehäuseschenkel

Drehstrom-Vibrationsmotor 0,20kW 1500 rpm 230/400V B3 Beine

Drehstrom-Vibrationsmotor 0,75kW 3000 rpm 230/400V B3 Beine

Drehstrom-Vibrationsmotor 0,08kW 3000 rpm 230/400V B3 Beine

Drehstrom-Vibrationsmotor 0,62kW 1500 rpm 230/400V B3 Beine

Drehstrom-Vibrationsmotor 1,1kW 1500 rpm 230/400V B3 Beine

Drehstrom-Vibrationsmotor 0,27kW 3000 rpm 230/400V B3 Beine

Einphasiger Vibrationsmotor 0,13kW 3000 rpm 230V B3 Beine

Drehstrom-Vibrationsmotor 0,30kW 1500 rpm 230/400V B3 Beine

Kunden, die diesen Artikel gekauft haben, kauften auch:

Eura Drives E2100 Serie 0,75 kW Vektorantrieb Dreiphasiger Frequenzumrichter

Drehstrommotor 0,55 kW 0,75 PS 230/400 V 750 rpm B5-Flansch-Aluminiumgehäuse

Drehstrommotor 1,1 kW 1,5PS 230/400 V 1500 rpm IE1 Flansch B3 Beine

Schneckenradgetriebe Größe 110 Flansch PAM 200/24 - Motorgehäuse 90 B5

Startseite

- Elektrische Ausrüstung

- Magnetothermische und Differentialschutzschalter

- Magnetisch-thermische Schutzschalter 1-polig

- Leistungsschalter 1-polig 1 bis 63A Kurve C - LS

- Leitungsschutzschalter 1-polig 1 bis 63A Kurve C - Hyundai

- Einpolige Leitungsschutzschalter 1-polig 1 bis 63A Kurve C - OMU

- Leistungsschalter 1-poliger 1 bis 63 A Kurven-D – Tracon

- Magnetothermie 1-polig 80 bis 125 - 10kA - Hyundai

- Leistungsschalter 1-poliger 1 bis 63 A Kurven-C– Tracon

- Magnetisch-thermische Schutzschalter 1-polig + Nullleiter DPN

- Leistungsschalter 2-polige

- Leistungsschalter 2-polige 2 bis 63A Kurve C - LS

- Leistungsschalter 2-polige 6A bis 63A - Hyundai

- Leitungsschutzschalter 2-polige 1A bis 63A - Schneider

- Leitungsschutzschalter 2-polige 63 bis 125 - 10kA - LS

- Leitungsschutzschalter 2-polige 80 bis 125 - 10kA - Hyundai

- Leitungsschutzschalter 2-poliger 1 bis 63 A Kurve D – Tracon

- Leitungsschutzschalter 2-polige 1 bis 63A C-Kurve - OMU

- Leitungsschutzschalter 2-poliger 1 bis 63 A Kurve C – Tracon

- Leitungsschutzschalter 2-poliger 6A bis 63A Kurve D - Hyundai

- Leitungsschutzschalter 2-polige 2 bis 63A Kurve D - LS

- Leistungsschalter 3-polige

- Leitungsschutzschalter 3-polige 1 bis 63A Kurve C - LS

- Leistungsschalter 3-polige 6A bis 63A, C-Kurve - Hyundai

- Leistungsschalter 3-polige 6A bis 63A - Schneider

- Leistungsschalter 3-poliger 1 bis 63 A Kurve D – Tracon

- Leitungsschutzschalter 3-polige 1 bis 63A C-Kurve - OMU

- Leistungsschalter 3-poliger 1 bis 63 A Kurve C – Tracon

- Leistungsschalter 3-polige 80A bis 125A - 10kA - Hyundai

- Leitungsschutzschalter 3-polige 63A bis 125A-10kA - LS

- Leistungsschalter 3-polige 6A bis Schalter 63A Kurve D – Hyundai

- Leistungsschalter 3-polige 2A bis 63A Kurve D - LS

- Leistungsschalter 4-polige

- Leitungsschutzschalter 4-polige 1 bis 63A Kurve C - LS

- Leitungsschutzschalter 4-polige 6 bis 63A - Hyundai

- Leitungsschutzschalter 4-polige 63A bis 125A - 10kA - LS

- Leitungsschutzschalter 4-polige 80A bis 125A - 10kA - Hyundai

- Leitungsschutzschalter 4-polig 1 bis 63 A Kurve D – Tracon

- Leitungsschutzschalter 4-polige 1 bis 63A C-Kurve - OMU

- Leitungsschutzschalter 4-polig 1 bis 63 A Kurve C – Tracon

- Leitungsschutzschalter 4-polige 6A bis 63A - Schneider

- Leitungsschutzschalter 4-polige Schalter 6A bis 63A Kurve D – Hyundai

- Leistungsschalter 1-polige + neutrale

- Gleichstrom-Schutzschalter

- Schutzschalter mit vergossenem Gehäuse

- Kompaktleistungsschalter 3-polige – Tracon

- Leistungsschalter mit gespritztem Gehäuse 3-polig - LS

- Leistungsschalter mit gespritztem Gehäuse 3-polig - Hyundai

- Kompaktleistungsschalter 4-polige – Tracon

- Leistungsschalter mit gespritztem Gehäuse 4-polig - LS

- Leistungsschalter mit gespritztem Gehäuse 4-polig - Hyundai

- Zubehör für Kompaktleistungsschalter – Tracon

- Zubehör für Leistungsschalter mit vergossenem Gehäuse - LS

- Zubehör für Leistungsschalter mit vergossenem Gehäuse - Hyundai

- Fehlerstrom-Schutzschalter

- Differentialschutzschalter der Klasse AC – Tracon

- Fehlerstrom-Schutzschalter der Klasse AC - LS

- Differenzial-Magnetothermoschalter der Klasse A-SI - Toscano

- Fehlerstrom-Schutzschalter der Klasse A - LSeries

- Differenzialschutzschalter der Klasse AC mit schmalem Profil – Tracon

- Differenzialschutzschalter der Klasse A mit schmalem Profil - Hyundai Electric

- Differenzial-Magnetothermoschalter der Klasse B-SI - Toscano

- Bipolares Differenzial (2-polig)

- Zweipoliges Differenzial (2-polig) 30mA Klasse AC

- Zweipoliges Differenzial (2-polig) 30mA Klasse A

- Zweipoliges Differenzial (2-polig) 30mA Klasse B

- Bipolare Differentiale (2 Pole) 30 mA Superimmunisiert

- Bipolar differentiell (2 Pole) 300mA Klasse AC

- Bipolar differentiell (2 Pole) 300mA Klasse A

- Bipolar differentiell (2 Pole) 300mA Klasse B

- Bipolare Differentiale (2 Pole) 300 mA Superimmunisiert

- Bipolares Differenzial (2-polig) 10mA Klasse AC

- Bipolare (2-polige) selektive Differentiale

- Selbstrückstellende zweipolige Differentiale

- Vierpoliges Differential (4 Pole)

- Dreiphasendifferenzial (4-polig) 30mA Klasse AC

- Dreiphasendifferenzial (4 Pole) 30mA Klasse A Immunisiert

- Dreiphasige Differentiale (4 Pole) 30 mA Superimmunisiert

- Dreiphasendifferenzial (4-polig) 30mA Klasse B

- Dreiphasen-Differential (4-polig) 300mA Klasse AC Standard

- Dreiphasendifferenzial (4 Pole) 300mA Klasse A Immunisiert

- Dreiphasige Differentiale (4 Pole) 300 mA Superimmunisiert

- Dreiphasendifferenzial (4-polig) 300mA Klasse B

- Dreiphasige (4-polige) selektive Fehlerstrom-Schutzschalter

- Selbstrückstellende dreiphasige (4-polige) Differentiale

- Dreiphasendifferenzial (4 Pole) 6mA Klasse A

- Industrielle Differenzialschutzrelais

- Modulare Trenner und Schalter

- Lasttrennschalter

- Eingebaute Schaltschränke

- Modulare Verteilerkästen

- Überspannungsableiter

- Schütze in Modulbauweise

- Zubehör für MCBs und RCDs

- Verbindungskämme

- Überwachungsrelais

- Elektrizitätszähler

- Magnetisch-thermische Schutzschalter 1-polig

- Schütze und Mini-Schütze

- Thermorelais

- Motorschutz Motorschutzschalter Motorschutz

- Direkt- und Stern-Dreieck-Starter, Softstarter

- Elektromagnetische und Halbleiterrelais

- Steuer- und Schutzrelais, Thermostate, Temperaturfühler

- Endschaltungen - positionsdetektoren - elektrische Pedale - Sensoren

- Schalter - Trennschalter

- 2-polige Nockenschalter

- Dreiphasige, 3-polige Lasttrennschalter

- 3-polige dreiphasige Nockenschalter 3-polig

- 4-polige vierpolige Trennschalter 4-polig

- 4-polige Nockenschalter

- Kastenmontierte Trennschalter

- Unterschranktrenner

- Wechselrichterschalter, Stern-Dreieck

- Schalter für die Leitungsumschaltung

- Schalter - Wahlschalter

- Wahlschalter für Messgeräte

- Zubehör für Trenn- und Nockenschalter

- Lasttrennschalter

- Kabelverschraubungen und elektrische Armaturen

- Befehl und Signalisierung

- Lotsen

- Elektrische Drucktasten

- Stopp- und Notfalltasten

- Selektoren

- Elektrische Wahlschalter Ø22mm Kunststoff

- Elektrische Wahlschalter Ø22mm aus Kunststoff Standard-Serie

- Elektrische Wahlschalter Ø22mm Kunststoff - NY Serie

- Elektrische Wahlschalter - Harmony XB5 Schneider

- Elektrische Wahlschalter Ø22mm Kunststoff - Giovenzana

- Elektrische Wahlschalter aus Kunststoff - EMS

- Elektrische Leuchtschalter Ø22mm aus Kunststoff - Serie NY

- Elektrische Wahlschalter Ø22mm aus Metall

- Elektrische Wahlschalter Ø22mm Kunststoff

- Monoblock-Kunststoffdrucktasten und -Wahlschalter

- Licht- und akustische Signalgeräte

- Drucktastenboxen

- Drucktastenboxen mit vorinstallierten Bedienelementen

- Komplette Drucktastenboxen und Drucktastenfelder für 1 Element

- Komplette Drucktasterboxen und Drucktasterfelder für 2 Elemente

- Komplette Drucktastenboxen und Drucktastenfelder für 3 Elemente

- Komplette Drucktastenboxen und Drucktastenfelder für 4 Elemente

- Spezielle komplette Drucktasterboxen und Tastaturen

- Motorisch gesteuerte Drucktasten

- Kästen und Elemente für Hebe- und Brückenkräne

- Inspektionskästen und Druckknopftafeln für Aufzüge

- Zubehör für Drucktaster der Serie 22mm

- Vandalismusgeschützte Taster und Schalter

- Schalter

- Verordnung

- Lotsen

- Hebezeuge - Brückenkräne - Hebezeuge

- Metallgehäuse und Schränke

- Thermoplastische und faserverstärkte Schränke und Gehäuse

- Verteilerkästen und -schränke

- Wasserdichtes ABS-Gehäuse mit Konus

- Vorgebohrte, wasserdichte ABS-Gehäuse

- Wasserdichte ABS-Gehäuse mit glatten Wänden

- Vorgestanzte, wasserdichte ABS-Gehäuse mit transparenten Deckeln

- Wasserdichte ABS-Gehäuse glatte Wände transparenter Deckel

- Montageplatte aus Stahl für wetterfeste ABS-Gehäuse

- Freie thermoplastische Gehäuse mit Konen

- Freistehende Gehäuse aus glattwandigem Thermoplast

- Thermoplastische wasserdichte Gehäuse mit Gewindeeingängen

- Wasserdichte Thermoplast-Gehäuse mit hohem Deckel

- Modulare Aufputz-Verteilerschränke

- Eingebaute Schaltschränke

- Steckdosenboxen

- Gehäuse für Bedienelemente Ø22mm

- ABS-Gehäuse

- Polyester-Schränke

- Gehäuse für Griffmaterial - extern

- Elektro- und Erdungskästen

- Belüftungssysteme

- Verteilerkästen und -schränke

- Anschluss- und Befestigungsmaterial

- Terminals

- Elektrische Anschlussverteiler

- Signalisierende Elemente

- Endstücke und Anschlussklemmen

- Steckverbinder für die Fotovoltaik

- Steckdosen

- Befestigung, Verdrahtungsschutz, Isolierband

- DIN-Schiene

- Schlitzrinne

- Kämme für den elektrischen Anschluss

- Isolatoren

- Flansche und Verbindungselemente

- Industrielle mehrpolige Steckverbinder

- Werkzeuge

- Terminals

- Timer - Schalter und Timer-Programmiergeräte

- Flexibler Schlauch

- Elektrische Kabel und Schläuche

- Sicherungen und Sicherungshalter

- Stromversorgungen

- Transformatoren und Spartransformatoren, Spannungsstabilisatoren, USV

- Einphasige Transformatoren

- Einphasentransformatoren IP-00

- 25VA IP-00 Einphasentransformatoren

- 40VA IP-00 Einphasentransformatoren

- 50VA IP-00 Einphasentransformatoren

- IP-00 60VA Einphasentransformatoren

- 63VA IP-00 Einphasentransformatoren

- 100VA IP-00 Einphasentransformatoren

- 150VA IP-00 Einphasentransformatoren

- 160VA IP-00 Einphasentransformatoren

- 200VA IP-00 Einphasentransformatoren

- 250VA IP-00 Einphasentransformatoren

- 300VA IP-00 Einphasentransformatoren

- 315VA IP-00 Einphasentransformatoren

- 400VA IP-00 Einphasentransformatoren

- Transformadores monofásicos IP-00 de 500VA

- IP-00 600VA Einphasentransformatoren

- 630VA IP-00 Einphasentransformatoren

- 750VA IP-00 Einphasentransformatoren

- 800VA IP-00 Einphasentransformatoren

- Transformadores monofásicos IP-00 de 1000VA

- Einphasentransformatoren IP-00 Spannungen je nach Anforderung

- Einphasentransformatoren IP-20

- Ultra-isolierte Einphasentransformatoren IP-20

- Ultra-isolierte Einphasentransformatoren IP23

- Rückspeisetransformatoren mit künstlichem Nullleiter IP23

- Einphasentransformatoren IP-00

- Sicherheitstransformatoren für Schwimmbadscheinwerfer

- Einphasige und dreiphasige Spartransformatoren

- Dreiphasige Transformatoren

- Ultra-isolierte Dreiphasen-Dreiphasen-Transformatoren in Stern-Dreieck-Ausführung

- Dreiphasen-Stern-Stern-Transformatoren

- Drehstromtransformatoren Spannungen je nach Anforderung

- Dreiphasige ultraisolierte Stern-Stern-Drehstromtransformatoren

- Dreiphasen-Ultraisolationstransformatoren Spannungen je nach Anforderung

- Dreiphasen-Einphasentransformatoren

- Ringkerntransformatoren

- Stromwandler

- Spannungsstabilisatoren

- USVS

- EMC/RFI-Filter

- Erdspieße und Zubehör

- Einphasige Transformatoren

- Automaten und Displays

- Erdungselemente

- Frequenzumrichter

- Einphasige Frequenzumrichter

- Einphasige Frequenzumrichter - Einphasige Frequenzumrichter - Einphasige Frequenzumrichter - Einphasige Frequenzumrichter Eura D

- Einphasige Frequenzumrichter - LS

- Einphasige Frequenzumrichter - Delta

- Einphasige Frequenzumrichter - Serie VDc

- Einphasige Frequenzumrichter - Serie VFC3

- Einphasige EMC/RFI-Filter

- Dreiphasige Frequenzumrichter

- Regulierungszubehör

- Einphasige Frequenzumrichter

- Kondensatoren

- Vakuumschalter, Druckschalter und Durchflussmesser

- Messgeräte

- Steuer- und Schutztafeln bereits verdrahtet

- Thermische Strahler

- Wandleuchten und Beleuchtungselemente

- Dienstleistungen

- Magnetothermische und Differentialschutzschalter

- Elektrische Motoren

- Dreiphasige Elektromotoren 230/400V und 400/690V IE1, IE2 und IE3

- Drehstrommotoren 3000 U/min (2-polig) IE1, IE2 und IE3

- Drehstrom-Elektromotoren 3000 U/min B3-Flansch (Beine) Kfz. Aluminium IE1, IE2, IE3

- Dreiphasen-Elektromotoren 3000 U/min Flansch B5 Aluminiumgehäuse IE1, IE2, IE3

- Dreiphasen-Elektromotoren 3000 U/min B14-Flansch IE, IE2, IE3 Aluminium-Gehäuse

- Dreiphasen-Elektromotoren 3000 rpm Flansch B35 (Beine) Aluminiumgehäuse

- Dreiphasen-Elektromotoren 3000 rpm Flansch B34 (Beine) Aluminiumgehäuse

- Drehstrom-Elektromotoren 3000 U/min Flansch B3 (Beine) Auto. Gusseisen

- Drehstrom-Elektromotoren 3000 U/min Flansch B5 Graugussgehäuse

- Drehstrom-Elektromotoren 3000 U/min Flansch B3 - Siemens

- Drehstrom-Elektromotoren 3000 U/min Flansch B5 - Siemens

- Drehstrom-Elektromotoren 3000 U/min Flansch B14 - Siemens

- Drehstrommotoren 1500 U/min (4-polig) IE1, IE2 und IE3

- Drehstrom-Elektromotoren 1500 U/min Flansch B3 (Legs) Aluminiumgehäuse IE1, IE2, IE3

- Dreiphasen-Elektromotoren 1500 U/min B5-Flansch IE1, IE2, IE3 Aluminium-Gehäuse

- Drehstrom-Elektromotoren 1500 U/min B14-Flansch IE1, IE2, IE3 Aluminium-Gehäuse

- Dreiphasen-Elektromotoren 1500 rpm Flansch B35 (Beine) Aluminiumgehäuse

- Dreiphasige Elektromotoren 1500 rpm Flansch B34 (Beine) Aluminiumgehäuse

- Drehstrom-Elektromotoren 1500 U/min Flansch B3 (Beine) Gusseisen

- Drehstrom-Elektromotor 1500 U/min B5-Flansch, Graugussgehäuse

- Drehstrom-Elektromotoren 1500 U/min Flansch B3 - Siemens

- Drehstrom-Elektromotoren 1500 U/min Flansch B5 - Siemens

- Drehstrom-Elektromotoren 1500 U/min B14-Flansch - Siemens

- Drehstrommotoren 1000 U/min (6-polig) IE1, IE2 und IE3

- Drehstrom-Elektromotoren 1000 U/min B3-Flansch (Füße) Aluminiumgehäuse IE1, IE2, IE3

- Dreiphasen-Elektromotoren 1000 U/min Flansch B5 Aluminiumgehäuse IE1, IE2, IE3

- Dreiphasen-Elektromotoren 1000 U/min Flansch B14 Aluminiumgehäuse IE1, IE2, IE3

- Drehstrom-Elektromotoren 1000 U/min Flansch B3 (Legs) Gussgehäuse

- Dreiphasige Elektromotoren 1000 U/min Flansch B5 aus Gusseisen.

- Dreiphasige Elektromotoren 1000 U/min Flansch B3 - Siemens

- Drehstrom-Elektromotoren 1000 U/min Flansch B5 - Siemens

- Drehstrom-Elektromotoren 1000 U/min B14-Flansch - Siemens

- Drehstrommotoren 750 U/min (8-polig) IE1

- Dreiphasen-Elektromotoren 750 U/min B3-Flansch (Beine) Aluminiumgehäuse

- Drehstrom-Elektromotoren 750 U/min Flansch B5 Aluminiumgehäuse

- Drehstrom-Elektromotoren 750 U/min Flansch B14 Aluminiumgehäuse

- Dreiphasen-Elektromotoren 750 U/min B3-Flansch (Beine) Gusseisengehäuse

- Drehstrom-Elektromotoren 750 U/min Flansch B5 Graugussgehäuse

- Drehstrom-Elektromotoren 750 U/min B14-Flansch - Siemens

- Drehstrommotoren 3000 U/min (2-polig) IE1, IE2 und IE3

- Einphasige Elektromotoren mit mittlerem und hohem Anlaufmoment.

- Einphasige Elektromotoren 3000 U/min halbes Anlaufmoment

- Einphasige Motoren 3000 U/min B3-Flansch (Beine) Mittleres Drehmoment

- Einphasige Motoren 3000 U/min B5-Flansch Mittleres Drehmoment

- Einphasenmotoren 3000 U/min B14-Flansch Mittleres Drehmoment

- Einphasenmotoren 3000 rpm Flansch B34 (Beine) Mittleres Drehmoment

- Einphasenmotoren 3000 rpm Flansch B35 (Beine) Mittleres Drehmoment

- Einphasige Elektromotoren mit 3000 U/min und hohem Anlaufmoment

- Einphasenmotoren 3000 U/min B3-Flansch (Legs) hohes Drehmoment

- Einphasige Motoren 3000 U/min B5-Flansch Hohes Drehmoment

- Einphasige Motoren 3000 U/min Flansch B14 hohes Drehmoment

- Einphasenmotoren 3000 rpm Flansch B34 (Beine) hohes Drehmoment

- Einphasenmotoren 3000 rpm Flansch B35 (Beine) hohes Drehmoment

- Einphasige Elektromotoren 1500 U/min halbes Anlaufmoment

- Einphasige Elektromotoren mit 1500 U/min und hohem Anlaufmoment

- Einphasenmotoren 1500 U/min B3 Flansch (Legs) hohes Anlaufmoment

- Einphasenmotoren 1500 U/min B5-Flansch mit hohem Drehmoment

- Einphasige Motoren 1500 U/min B14 Flansch hohes Drehmoment

- Einphasenmotoren 1500 rpm Flansch B34 (Beine) hohes Drehmoment

- Einphasenmotoren 1500 rpm Flansch B35 (Beine) hohes Drehmoment

- Einphasige Elektromotoren mit 1000 U/min und hohem Anlaufmoment

- Einphasige Elektromotoren 3000 U/min halbes Anlaufmoment

- Elektromotoren mit Bremse

- Motoren für Betonmischer

- Vibrationsmotoren

- Anlasser für Elektromotoren

- Spannsockel und Führungen für Elektromotoren

- Zubehör und Ersatzteile für Elektromotoren

- Frequenzumrichter

- Einphasige Frequenzumrichter

- Einphasige Frequenzumrichter - Einphasige Frequenzumrichter - Einphasige Frequenzumrichter - Einphasige Frequenzumrichter Eura D

- Einphasige Frequenzumrichter - LS

- Einphasige Frequenzumrichter - Delta

- Einphasige Frequenzumrichter - Serie VDc

- Einphasige Frequenzumrichter - Serie VFC3

- Einphasige EMC/RFI-Filter

- Dreiphasige Frequenzumrichter

- Regulierungszubehör

- Einphasige Frequenzumrichter

- Schwimmbad-Pumpen

- Treibriemen für Motoren

- Keilriemen für Motoren

- Klassische Keilriemen der Z-Serie für Motoren

- Keilriemen klassisch Serie A für Motoren

- Klassische Keilriemen der Serie B für Motoren

- Klassische Keilriemen der Serie C für Motoren

- Keilriemen Keilriemen SPZ metrische Serie für Motoren

- Keilriemen metrisch Serie SPA für Motoren

- Keilriemen Keilriemen metrisch Serie SPB für Motoren

- Keilriemen SPC metrische Serie für Motoren

- Verzahnte Keilriemen für Motoren

- Keilriemen für Motoren

- Riemenscheiben zur Kraftübertragung für Elektromotoren

- Taper Lock Taper-Buchsen für Riemenscheiben

- Dreiphasige Elektromotoren 230/400V und 400/690V IE1, IE2 und IE3

- Getriebe

- Pneumatisches Material

- Pneumatische Zylinder

- Pneumatikzylinder mit einem Durchmesser von 8 bis 25 mm

- Kompakte Pneumatikzylinder Durchmesser 12 bis 100mm

- Kompakte Pneumatikzylinder ISO 21287

- UNITOP Kompakte Pneumatikzylinder

- Kompakte Pneumatikzylinder Ø12

- Kompakte Pneumatikzylinder Ø16

- Kompakte Pneumatikzylinder Ø20

- Kompakte Pneumatikzylinder Ø25

- Kompakte Pneumatikzylinder Ø32

- Kompakte Pneumatikzylinder Ø40

- Kompakte Pneumatikzylinder Ø50

- Kompakte Pneumatikzylinder Ø63

- Kompakte Pneumatikzylinder Ø80

- Kompakte Pneumatikzylinder Ø100

- Kompakte Pneumatikzylinder ISO 21287

- Pneumatikzylinder mit einem Durchmesser von 32 bis 125 mm

- Kompakte geführte Pneumatikzylinder mit Durchmessern von 6 bis 63 mm

- Kompakte Pneumatikzylinder mit doppelter Führung, Durchmesser 6 bis 63 mm

- Kompakte Doppelführungs-Pneumatikzylinder Ø6

- Kompakte Doppelführungs-Pneumatikzylinder Ø10

- Kompakte Doppelführungs-Pneumatikzylinder Ø12

- Kompakte Doppelführungs-Pneumatikzylinder Ø16

- Kompakte Doppelführungs-Pneumatikzylinder Ø20

- Kompakte Doppelführungs-Pneumatikzylinder Ø25

- Kompakte Doppelführungs-Pneumatikzylinder Ø32

- Kompakte Doppelführungs-Pneumatikzylinder Ø40

- Kompakte Doppelführungs-Pneumatikzylinder Ø50

- Kompakte Doppelführungs-Pneumatikzylinder Ø63

- Kompakte Pneumatikzylinder mit parallelen Stangendurchmessern von 6 bis 32 mm

- Kompakte Pneumatikzylinder mit Ø6 Parallelstangen

- Kompakte Pneumatikzylinder mit Ø12 Parallelstangen

- Kompakte Pneumatikzylinder mit Parallelstangen Ø16

- Kompakte Pneumatikzylinder mit Ø20 Parallelstangen

- Cilindros neumáticos compactos vástagos paralelos Ø25

- Kompakte Pneumatikzylinder mit Parallelstangen Ø32

- Kompakte Pneumatikzylinder mit doppelter Führung, Durchmesser 6 bis 63 mm

- Zubehör für Druckluftzylinder

- Elektromagnetische Ventile

- Pneumatische Ventile

- Druckluftfiltrations- und -aufbereitungsanlagen

- Verschiedene Materialien Pneumatik

- Durchflussregler, pneumatische Anschlüsse

- Durchfluss- und Druckregler

- Abgasregulatoren

- Schnell-Kupplungen

- Fittings für die Lebensmittelindustrie

- Fittings

- Automatische Kupplung - Serie 60000 INOX

- Zubehör - Serie 62000 INOX

- Gerade konische Kerne – Serie 62000 INOX

- Erweiterungen - Serie 62000 INOX

- Fittings – Serie 62000 INOX

- Konische Reduzierungen – Serie 62000 INOX

- Schraubverschlüsse - Serie 62000 INOX

- Spikes - Serie 62000 INOX

- Fittings - Serie durchführungen INOX

- „T“ Fittings – Serie 62000 INOX

- „L“ Fittings – Serie 62000 INOX

- „Y“ Fittings – Serie 62000 INOX

- Schalldämpfer - Serie 62000 INOX

- Schnellkupplungen und Adapter – Serie 63000 INOX

- Automatische Kupplung - Serie 60000 INOX

- Gerade Beschläge

- Gerade Metallverschraubung mit Außengewinde - - Außengewinde Metal Work

- Gerader Metallanschluss mit Außengewinde, Serie C – Metal Work

- Gerade Metallverschraubung mit konischem Außengewinde, Serie C – Metal Work

- Gerader Metallanschluss mit konischem Außengewinde Serie 1000 - Aignep

- Gerade verstellbare Metallarmatur mit Außengewinde Serie 1000 - Aignep

- Gerader Metallanschluss mit Außengewinde Serie 1000 - Aignep

- Gerade Metallverschraubungen mit Außengewinde Serie 50000 - Aignep

- Gerade Metallverschraubung mit Außengewinde Serie 55000 - Aignep

- Gerader Metallanschluss mit Außengewinde Serie 56000 MINI - Aignep

- Gerade Metallverschraubung mit Innengewinde - Metal Work

- Gerader Metallanschluss mit Innengewinde, Serie C – Metal Work

- Gerade Metallverschraubung mit Innengewinde Serie 1000 - Aignep

- Gerade Metallverschraubung mit Innengewinde Serie 50000- Aignep

- Gerade Metallverschraubungen mit Innengewinde Serie 55000 - Aignep

- Gerade Metallverschraubung mit Außen- und Innengewindefeder Serie 1000 - Aignep

- Gerade Metallverschraubung mit konischer Außengewindefeder Serie 1000 - Aignep

- Racor recto orientable metálico con muelle rosca macho cónica Serie 1000 - Aignep

- Gerader, ausrichtbarer Metallanschluss mit Außengewindefeder Serie 1000 - Aignep

- Gerade Metallverschraubung mit Außengewindefeder Serie 1000 - Aignep

- Gerade Metallverschraubung mit Innengewindefeder Serie 1000 - Aignep

- Gerade Metallverschraubung mit konischem Außengewinde Serie 58000 - Aignep

- Fittings schwenkbarer Krümmer

- Drehbare Fittings aus Technopolymer – Metal Work

- Verlängerte, drehbare Fittings mit Außengewinde aus Technopolymer – Metal Work

- Drehbare Fittings mit Außengewinde, Serie 1000 – Aignep

- Fittings mit Außengewinde Serie 1000 - Aignep

- Fittings schwenkbare Bögen mit Außengewinde Serie 50000 - Aignep

- Drehbare Fittings mit Außengewinde – Metal Work

- Konische und zylindrische Fittings mit Außengewinde, Serie C – Metal Work

- Fittings schwenkbare Bögen mit Außengewinde Serie 55000 - Aignep

- Drehbare Fittings mit Außengewinde Serie 56000 MINI - Aignep

- Konische Fittings mit Außengewinde Serie 58000 - Aignep

- Konische, verstellbare Fittings mit Außengewinde, Serie 58000 – Aignep

- Fittings mit Innengewinde Serie 1000 - Aignep

- Fittings mit Innengewinde der Serie C – Metal Work

- Fittings schwenkbares Innengewinde Serie 50000 - Aignep

- Drehbare Fittings aus Technopolymer – Metal Work

- Fittings schwenkbare Rohrbögen mit Innengewinde Serie 55000 - Aignep

- Drehbare Fittings mit kurzem, glattem Nippel, Serie 55000 – Aignep

- Drehbare Fittings mit langem, glattem Schaft, Serie 55000 – Aignep

- Fittings mit kurzem und langem spike aus Technopolymer - Metal Work

- 45° drehbare Fittings mit kurzem, glattem Nippel, Serie 55000 – Aignep

- 45 drehbare Fittings mit Außengewinde, Serie 55000 – Aignep

- Zwischengeschaltete "T"-Anschlüsse

- Zwischen-T Fittings aus Technopolymer - Metal Work

- Zwischen-T Fittings – Metal Work

- Zwischen-T Fittings der C-Serie – Metal Work

- Zwischen-T- Fittings mit mittlerem und seitlichem Gewinde – Metal Work

- Zwischen-T- Fittings mit mittlerem und seitlichem Gewinde, Serie C – Metal Work

- Zwischen-T- Fittings Serie 1000 – Aignep

- Racores T intermedios Serie 50000 - Aignep

- Fittings T-Stücke der Serie 55000 - Aignep

- Zwischen-T- Fittings Serie 56000 MINI - Aignep

- Zwischen-T- Fittings Serie 58000 – Aignep

- Zwischen-T- Fittings mit Zentralgewinde Serie 1000 - Aignep

- Zentralgewinde-T- Fittings aus Technopolymer – Metal Work

- T- Fittings mit verlängertem Zentralgewinde aus Technopolymer – Metal Work

- Fittings T-Stücke mit Mittelgewinde Serie 50000 - Aignep

- Fittings T-Stücke mit Mittelgewinde Serie 55000 - Aignep

- Zwischen-T- Fittings mit zentralem Innengewinde aus Technopolymer – Metal Work

- Zwischen-T- Fittings mit zentralem und seitlichem Gewinde Serie 56000 MINI - Aignep

- Zwischen-T- Fittings , konisches Außengewinde, Serie 1000 – Aignep

- Fittings Zwischen-T-Stücke, seitliches Gewinde Serie 50000 - Aignep

- Fittings T-Stücke mit seitlichem Gewinde Serie 55000 - Aignep

- T Fittings mit seitlichem Adapter Serie 55000 - Aignep

- T Fittings mit Zentraladapter Serie 55000 - Aignep

- T Fittings mit zentralem und seitlichem Adapter aus Technopolymer - Metal Work

- Verstellbare T Fittings mit kurzem, glattem Schaft, Serie 55000 – Aignep

- Fittings - Metal Work

- Fittings Serie C – Metal Work

- Fittings Serie 1000 - Aignep

- Zwischengeschaltete "Y"-Anschlüsse

- Fittings „Y“ aus Technopolymer – Metal Work

- Zwischenmännliche „Y“ Fittings aus Technopolymer – Metal Work

- Fittings zwischenstufe "Y" Serie 50000 Aignep

- Fittings zwischenstufe "Y" 55000-Serie Aignep

- Doppelte Fittings „Y“ aus Technopolymer – Metal Work

- Doppelte Fittings „Y“ Serie 55000 – Aignep

- Metall-"Y"-Anschlüsse mit Gewinde

- Fittings „Y“ mit Technopolymer-Adapter – Metal Work

- Männliche seitliche „Y“ Fittings aus Technopolymer – Metal Work

- Gerade Zwischenstücke

- Mittlerer gerader Anschluss – Metal work

- Racor recto intermedio Serie C - Metal work

- Mittlerer gerader Anschluss Serie 1000 - Aignep

- Gerade Zwischenverschraubung Serie 50000 - Aignep

- Gerade Zwischenverschraubung Serie 55000 - Aignep

- Zwischenstück gerade Serie 56000 MINI - Aignep

- Zwischengerader Anschluss Serie 58000 – Aignep

- Gerade Zwischenverschraubung aus Technopolymer – Metal work

- Zwischenbögen

- Zwischen- Fittings aus Technopolymer - Metal Work

- Fittings – Metal Work

- Zwischen- Fittings der C-Serie – Metal Work

- Zwischen- Fittings Serie 1000 - Aignep

- Fittings zwischenkrümmer Serie 50000 - Aignep

- Fittings zwischenkrümmer Serie 55000 - Aignep

- Zwischen- Fittings Serie 56000 MINI - Aignep

- Zwischen- Fittings Serie 58000 – Aignep

- Zwischen- Fittings bei 45 Serie 55000 – Aignep

- Drehbare Beschläge

- Fittings einfach lenkbar - Serie Basic

- Einfache Fittings – Metal Work

- Einfache verstellbare Fittings – Metal Work

- Einfache Fittings aus Technopolymer - Metal Work

- Fittings einfach schwenkbar Serie 50000 - Aignep

- Fittings doppelt schwenkbar Serie 50000 - Aignep

- Doppelte Fittings – Metal Work

- Doppelt verstellbare Fittings – Metal Work

- Fittings aus Technopolymer - Metal Work

- Einfache verstellbare 2-Körper- Fittings – Metal Work

- Einfache 2- und 3-Körper- Fittings – Metal Work

- Doppelte 2-teilige verstellbare Fittings – Metal Work

- Fittings 2 und 3 Körper - Metal Work

- Schrauben für pneumatische Verschraubungen

- Drehbare Ringe

- Einzelne drehbare Ringe - Einzelne drehbare Ringe - Einzelne drehbare Ringe - Einzelne drehbare Ringe - Einzelne drehbare Ringe

- Einfache Ringe und Gewinderinge Serie D – Metal Work

- Einfache Doppelkegelringe Serie D – Metal Work

- Einfache verstellbare Ringe aus Technopolymer – Metal Work

- Einfache verstellbare Ringe Serie 1000 - Aignep

- Einzelne Drehringe Serie 50000 - Aignep

- Einfache verstellbare Ringe Serie 55000 - Aignep

- Doppelt verstellbare Ringe Serie 1000 - Aignep

- Doppeldrehringe Serie 50000 - Aignep

- Doppelt verstellbare Ringe – Metal Work

- Doppelringe der D-Serie – Metal Work

- Doppelt verstellbare Ringe Serie 55000 - Aignep

- Doppelt verstellbare Ringe aus Technopolymer – Metal Work

- Gerade zylindrische Gewindebohrer

- Verschraubungen mit Innengewinde

- Pneumatische Stopfen und Reduzierstücke

- T-Stücke mit Metallgewinde

- Nippel und Adapter für den pneumatischen Anschluss

- Schottverschraubungen

- Fittings durchführungen - Aignep

- Racores pasamuros - Metal Work

- Racores pasamuros Serie C - Metal Work

- Fittings mit gerader durchführungen , Serie 1000 – Aignep

- Fittings durchführungen Baureihe 50000 - Aignep

- Fittings durchführungen Serie 55000 - Aignep

- Serie durchführungen Fittings Aignep

- Fittings durchführungen frauen Serie 50000 - Aignep

- Fittings durchführungen frauen 55000 Serie - Aignep

- Fittings durchführungen l-Reihe 55000 - Aignep

- Pneumatische Schalldämpfer

- Reifenhändler

- Muttern und Verschraubungen für pneumatische Elemente

- Zusammen

- Gewerkschaften

- Durchfluss- und Druckregler

- Pneumatische und Zubehör

- Druckschalter, Vakuumschalter und Durchflussmesser

- Ventile mit pneumatischen Antrieben

- Pneumatische Druckverstärker (Booster) - Luftbehälter

- Wasserfiltrations- und -aufbereitungsanlagen

- Hydraulische Stoßdämpfer

- Ersatzteile und Zubehör für Kompressoren

- Pneumatische Zylinder

- Druckluftnetze

- Rohr für Druckluftinstallationen

- Schnellstecker und Anschlüsse für Druckluftinstallationen

- Union für Druckluftinstallationen

- Elemente für Fallrohre und Abzweige für Druckluftanlagen

- Absperrventile für Druckluftanlagen

- Steckdosen

- Ergänzungen für Druckluftnetze

- Zubehör und Werkzeuge

- Zubehör und Verbindungselemente für Druckluftsysteme

- Ersatzteile und Zubehör für Kompressoren

- Lager

- Kugellager

- Öldichtungen

- Schrägkugellager

- Kugellager und Buchsen

- Kugellager

- Kugellager

- Kugellager

- Muttern, Scheiben und Befestigungshülsen

- Lagerträger und Spanner

- Fußstützen mit Gusslagern

- Reduzierte Brückenträger mit Gusslagern

- Ovale Gehäuse mit Gusslagern

- Quadratische Gehäuse mit Gusslagern

- Viereckige Konsole mit Gusslagern - - Viereckige Konsole mit Gusslagern - - Viereckige Konsole mit Gusslagern - ISB

- Viereckige Konsole mit Gusslagern - - Viereckige Konsole mit Gusslagern - - Viereckige Konsole mit Gusslagern - SNR

- Viereckige Konsole mit Gusslagern - - Viereckige Konsole mit Gusslagern - - Viereckige Konsole mit Gusslagern - INA

- Runde Stütze mit Gusseisenlagern

- Spannstütze mit Gusseisenlagern

- Fußstützen mit Lagern aus gestanztem Blech

- runde Flansch mit gestanzten Blechlagern

- Dreieckige Flansch mit Lagern aus gestanztem Blech

- Ovale Flansch mit gestanzten Blechlagern

- Fußstützen mit Edelstahllagern aus Thermoplast

- Ovale Stützen mit Edelstahllagern aus Thermoplast

- Vierkantstützen mit Edelstahllagern aus Thermoplast

- Rundstützen mit Edelstahllagern aus Thermoplast

- Zugträger mit Edelstahllagern aus Thermoplast

- Flanschlager mit Edelstahllagern aus Thermoplast

- Fußstützen mit Edelstahllagern

- Reduzierte Brückenstützen mit Edelstahllagern

- Ovale Stützen mit Edelstahllagern

- Vierkantstützen mit Edelstahllagern

- Runde Stützen mit INOX-Lagern

- Spannstützen mit INOX-Lagern

- Flanschlager mit INOX-Lagern

- Fußstützen mit Lagern - Serie aus leichter Aluminiumlegierung

- Ovale Lagerhalterungen - Serie aus leichter Aluminiumlegierung

- Präzisionsstützen

- Gleitlager aus Blech und Sinterbronze

- Kugellager

- Mechanische Ausrüstung

- Stützen und Spanner mit Lagern

- Fußstützen mit Gusseisenlagern

- Reduzierte Brückenträger mit Gusslagern

- Ovale Stützen mit Gusseisenlagern

- Quadratische Stützen mit Gusseisenlagern

- Runde Stütze mit Gusseisenlagern

- Spannstütze mit Gusseisenlagern

- Fußstützen mit Lagern aus gestanztem Blech

- Ovale Flansch mit gestanzten Blechlagern

- runde Flansch mit gestanzten Blechlagern

- Dreieckige Flansch mit Lagern aus gestanztem Blech

- Fußstützen mit Edelstahllagern aus Thermoplast

- Ovale Stützen mit Edelstahllagern aus Thermoplast

- Vierkantstützen mit Edelstahllagern aus Thermoplast

- Runde Stützen mit INOX-Thermoplastlagern

- Zugträger mit Edelstahllagern aus Thermoplast

- Flanschlager mit Edelstahllagern aus Thermoplast

- Fußstützen mit Edelstahllagern

- Reduzierte Brückenstützen mit Edelstahllagern

- Ovale Stützen mit Edelstahllagern

- Vierkantstützen mit Edelstahllagern

- Rundstützen mit Edelstahllagern

- Zugstützen mit Edelstahllagern

- Flanschlager mit Edelstahllagern

- Fußstützen mit Lagern - Serie aus leichter Aluminiumlegierung

- Ovale Lagerhalterungen - Serie aus leichter Aluminiumlegierung

- Präzisionsstützen

- Muttern, Scheiben und Befestigungshülsen

- Gleitschlitten und Führungen

- Präzisionsspindeln, Muttern und Halterungen

- Kugelgelenke, Stangenköpfe und Gabelköpfe

- Gleitlager aus Blech und Sinterbronze

- Öldichtungen

- Elastische Präzisionskupplungen

- Zahnräder und Zahnstangen

- Ritzel, Ketten, Räder, Taper-Lock-Buchsen und Scheiben

- Rollenketten Europäische Norm ISO DIN 8187

- Einfachrollenketten -ISO-Norm

- Doppelrollenketten ISO-Norm

- Dreifach-Rollenketten nach ISO-Norm

- Einzelglieder für ISO-Norm-Einzelrollenkette

- Doppelgelenke für ISO-Norm-Doppelrollenketten

- Dreifachgelenke für ISO-Norm-Dreifachrollenketten

- Einzelbiegungen für Standard-ISO-Einzelrollenketten

- Doppelwinkel für Standard-ISO-Doppelrollenketten

- Dreifachwinkel für ISO-Norm-Dreifach-Rollenketten

- Rollenketten American Standard ASA DIN 8188

- ASA Standard-Einzelrollenketten

- ASA Standard Doppelrollenketten

- ASA Standard-Dreifach-Rollenketten

- Einzelglieder für ASA Standard-Einzelrollenketten

- Doppelglieder für ASA Standard Doppelrollenketten

- Dreifachgelenke für ASA Standard-Dreifach-Rollenketten

- Einzelne Bögen für ASA-Standard-Einzelrollen

- Standard ASA-Doppelbiegungen für Ketten mit Standard-Doppelrollen

- ASA-Standard-Dreifach-Kettenbügel ASA-Standard-Dreifach-Rollenkettenbügel

- Rollenketten aus nichtrostendem Stahl Europäische Norm ISO DIN 8187

- ISO-Edelstahl-Einfachrollenketten

- ISO-Edelstahl-Doppelrollenketten

- ISO-Edelstahl-Dreifach-Rollenketten

- Einzelne Gelenke aus rostfreiem Stahl für ISO-Einzelrollenketten

- Doppelgelenke aus rostfreiem Stahl für ISO-Doppelrollenketten

- Dreifach-Edelstahlgelenke für Dreifach-ISO-Rollenketten

- Einzelne Edelstahlbügel für einfache ISO-Rollenketten

- Doppelte Edelstahlbügel für doppelte ISO-Rollenketten

- Dreifachbögen aus Edelstahl für dreifache ISO-Rollenketten

- Rollenketten aus rostfreiem Stahl American Standard ASA DIN 8188

- Verstärkte Rollenketten American Standard ASA DIN 8188

- ASA-Verstärkte Einzelrollenketten

- ASA-verstärkte Doppelrollenketten

- ASA-verstärkte Dreifach-Rollenketten

- Verstärkte Einzelglieder für ASA-Einzelrollenketten

- Verstärkte Doppelglieder für ASA-Doppelrollenketten

- Verstärkte Einzelbögen für Einfach-Rollenkette ASA

- Verstärkte Doppelbögen für ASA-Doppelrollenketten

- Rollenketten Gerade laufende Maschen Europäische Norm ISO DIN 8187

- Spezialisierte Rollenketten

- Konische Buchsen für Ritzel- Taper Lock Buchsen

- Ritzel für Taper-Lock DIN 8187-ISO/R606

- Kettenräder für Rollenketten DIN8187 - ISO/R606

- Einzelne Kettenräder für Rollenketten DIN8187 - ISO/R606

- Doppelkettenräder für Rollenketten ISO DIN 606

- Doppelzahnräder für Rollenketten 06B-2

- Doppelkettenräder für Rollenkette 08B-2

- Doppelkettenräder für Rollenkette 10B-2

- Doppelzahnräder für Rollenketten 12B-2

- Doppelzahnräder für Rollenketten 16B-2

- Doppelzahnräder für Rollenketten 20B-2

- Doppelzahnräder für Rollenketten 24B-2

- Doppelzahnräder für Rollenketten 28B-2

- Doppelkettenräder für Rollenkette 32B-2

- Dreifach-Kettenräder für Rollenketten ISO DIN 606

- Kettenräder oder Spannräder DIN 606

- Verzahnte Scheiben oder Zahnkränze ISO DIN 606 - DIN 8187 - ASA DIN 8188

- Verzahnte Scheiben oder Zahnkränze 3/8 x 7/32 ISO 06B-1-2-3 DIN 606

- Verzahnte Scheiben oder Zahnkränze 1/2 x 5/16 ISO 08B-1-2-3 DIN 606

- Verzahnte Scheiben oder Zahnkränze 5/8 x 3/8 mm ISO 10B-1-2-3 DIN 606

- Verzahnte Scheiben oder Zahnkränze 3/4 x 7/16 ISO 12B-1-2-3 DIN 606

- Verzahnte Scheiben oder Zahnkränze 1 x 17,02 ISO 16B-1-2-3 DIN 606

- Verzahnte Scheiben oder Zahnkränze 1 1/4 x 3/4 ISO 20B-1-2-3 DIN 606

- Verzahnte Scheiben oder Zahnkränze 1 1/2 x 1 ISO 24B-1-2-3 DIN 606

- Verzahnte Scheiben oder Zahnkränze 1 3/4 x 1 1/4 ISO 28B-1-2-3 DIN 606

- Verzahnte Scheiben oder Zahnkränze 2 x 1 1/4 ISO 32B-1-2-3 DIN 606

- Verzahnte Scheiben oder Zahnkränze 1/2 x 1/8 ISO 081-1 DIN8187 606

- Rollenketten Europäische Norm ISO DIN 8187

- Kraftübertragungsriemen

- Riemenscheiben für die Kraftübertragung

- V-Profil V-Scheiben Riemenscheiben

- Trapezförmige Blindscheiben

- Keilriemenscheiben für Taper Taper Buchsen

- Keilriemenscheiben für Taper Taper Buchse - 1 Rille

- Keilriemenscheiben für Taper Taper Bush - 2 Rillen

- Keilriemenscheiben für Taper Taper Bush - 3 Rillen

- Keilriemenscheiben für Taper Taper Bush - 4 Rillen

- Keilriemenscheiben für Taper Taper Bush - 5 Rillen

- Keilriemenscheiben für Taper Taper Bush - 6 Rillen

- Keilriemenscheiben Serie SPZ

- Keilriemenscheiben Serie SPA

- Keilriemenscheiben Serie SPB

- Keilriemenscheiben Serie SPC

- Keilriemenscheiben komplett mit Taper

- Tapered Taper Lock-Buchsen für Riemenscheiben und Kettenräder

- V-Profil V-Scheiben Riemenscheiben

- Aluminiumprofile

- Stützen und Spanner mit Lagern

- Erneuerbare Energien

- Hardware

- Zone Outlet

- Hersteller

- Schneider Electric

- Giovenzana

- Automatisierung

- Phoenix-Nockenschalter – Giovenzana

- Phoenix-Nockenschalter zur Befestigung des hinteren Rahmens – Giovenzana

- Schaltet 0-1 Typ R (Reverse-Box) – Giovenzana

- Ausführungen für Schalter 0-1 Typ R (Rückwandbefestigung)

- Schalter 1-0-2 Typ R (Reverse-Box) - Giovenzana

- Ausführungen für Schalter 1-0-2 Typ R (Befestigung an der Rückseite)

- Motorsteuerschalter zur Befestigung des hinteren Rahmens

- Ausführungen für Motorantriebsschalter (Rückwandbefestigung)

- Komplette Backplane-Schalter der Phoenix-Serie – Giovenzana

- Phoenix-Nockenschalter zur Befestigung des hinteren Rahmens – Giovenzana

- Regolus-Trennschalter – Giovenzana

- Steuerhilfsmittel und Pedalschalter - Giovenzana

- Endschaltungen – Positionsschalter

- Phoenix-Nockenschalter – Giovenzana

- Aufzüge – Höhe – Rolltreppen

- Automatisierung

- EMS

- DELTA

- Toscano

- Promax

- AIGNEP

- Fittings

- Zubehörserie

- 2010 Zylindrischer Stecker

- 2030 Machón cilíndrico de reducción

- 2050 Zylindrische Union männlich-weiblich

- 2090 Zylindrische Reduzierung

- 2095 Zylindrische Reduzierung

- 2096 Mutter

- 3000 weibliche Manschette

- 3015 Zylindrischer Innensechskant- Stecker

- 3026 Kurzer zylindrischer Innensechskant- Stecker

- 3044 Zylindrischer Zapfen mit O-Ring

- 3060 Trennwanddurchführungsbeschlag

- 4000 weibliches T-Stück

- 5050 L-Anschluss 90°-Befestigung mit Halterung

- Kreuzbeschlag aus 6040 Aluminium

- 6047 einfach Aluminiumband

- 6048 Doppelter Aluminiumstreifen

- 82242 Zylindrischer Adapter Buchse - Stecker. NPTF

- 82320 Kurzer allen - Stecker mit NBR-Gewinde

- 1000er Serie

- 1000 Konisches, gerades Außengewinde

- 1010 Konischer männlicher, verstellbarer gerader Anschluss

- 1015 Gerades, zylindrisches, verstellbares Außengewinde mit O-Ring

- 1020 Zylindrisches, gerades Außengewinde mit O-Ring

- 1021 Gerades Außengewinde mit O-Ring mit metrischem Gewinde

- 1025 Konisches, gerades Außengewinde mit Mutter und Feder

- 1026 Konisches, gerades, verstellbares Außengewinde mit Mutter und Feder

- 1027 Gerades, zylindrisches, verstellbares Außengewinde mit O-Ring, Mutter und Feder

- 1028 Gerades zylindrisches Außengewinde mit O-Ring, Mutter und Feder

- 1029 Gerades Außengewinde mit metrischem Gewinde, Mutter und Feder

- 1030 Gerades Anschlussstück mit Innengewinde

- 1035 Gerades Innengewinde mit Mutter und Feder

- 1040 Mittlerer gerader Anschluss

- 1050 Gerade Zwischenschottverschraubung

- 1100 Konischer männlicher L-Anschluss

- 1101 L-Außengewinde mit metrischem Gewinde

- 1110 Konischer, männlicher, verstellbarer L-Anschluss

- 1115 Verstellbares L-förmiges zylindrisches Außengewinde mit O-Ring

- 1120 weiblicher L-Anschluss

- 1130 Zwischen-L-Anschluss

- 1200 Konischer zentraler T-Stecker mit Außengewinde

- 1210 Konisches, zentrales, verstellbares T-Stück mit Außengewinde

- 1215 Zentrales, zylindrisches, verstellbares T-Stück mit Außengewinde und O-Ring

- 1220 Konischer seitlicher T-Anschluss mit Außengewinde

- 1230 Zwischen-T-Anschlussstück

- 1300 Zwischenkreuzbeschlag

- 1500 einfach verstellbarer Ring

- 1510 Doppelter verstellbarer Ring

- 1600 Aluminium-Unterlegscheibe

- 1610 gezackte aus Nylon PA66

- 1612 Bi-Material-Unterlegscheibe Stahl und NBR

- 1613 Selbstzentrierende Unterlegscheibe aus Bi-Material Stahl und NBR

- 1700 Sicherungsmutter

- 1710 Sicherungsmutter mit Feder

- 50000er Serie

- 50020 Gerades zylindrisches Außengewinde mit O-Ring

- 50030 Gerades Anschlussstück mit Innengewinde

- 50040 Racor rector intermedio

- 50050 Gerade Zwischenschottverschraubung

- 50055 Zwischen-Schottverschraubung mit geradem Innengewinde

- 50106 Weiblicher, verstellbarer L-Anschluss

- 50116 Verstellbares L-förmiges zylindrisches Außengewinde mit O-Ring

- 50126 Verlängertes, verstellbares L-förmiges zylindrisches Außengewinde mit O-Ring

- 50130 Zwischen-L-Anschlussstück

- 50200 Konischer zentraler T-Stecker mit Außengewinde

- 50216 Verstellbarer zentraler zylindrischer T-Stecker mit Außengewinde und O-Ring

- 50226 Verstellbarer zylindrischer seitlicher T-Stecker mit Außengewinde und O-Ring

- 50230 T-Zwischenstück

- 50310 Y-Zwischenstück

- 50326 Verstellbarer zylindrischer Y-Stecker mit O-Ring

- 50500 einfach verstellbarer Ring

- 50510 Doppelter verstellbarer Ring

- 51410 einfach

- 51420 Doppelschraube

- 51430 Dreifachschraube

- 51440 einfach mit Außen- und Innengewinde

- 50550 einfach verstellbare Armatur mit O-Ring

- 50560 Doppelt verstellbarer Fitting mit O-Ring

- 50600 Zylindrischer Außenadapter mit O-Ring

- 50610 Stecker

- 50625 Union

- 50700 Ermäßigung

- 50900 5- Wege Aluminiumstreifen

- 55000-Serie

- 50010N Gerades zylindrisches Außengewinde mit Innensechskant-O-Ring

- 50020N Gerades zylindrisches Außengewinde mit O-Ring

- 50030N Gerades Innengewinde

- 55040 Zwischenführungsbeschlag

- 50050N Gerade Zwischenschottverschraubung

- 55050 Gerade Zwischenschottverschraubung

- 50055N Zwischen-Schottverschraubung mit geradem Innengewinde

- 55060 Ausrichtbares Zwischenstück in L-Form für Schott

- 55106 Zylindrisches, verstellbares L-Fitting mit Innengewinde

- 55111 Konischer männlicher verstellbarer L-Anschluss (kurz)

- 55116 Verstellbares L-förmiges zylindrisches Außengewinde mit O-Ring

- 55126 Verlängertes, verstellbares L-förmiges zylindrisches Außengewinde

- 55130 L-Zwischenstück

- 55140 Verstellbarer L-förmiger Anschluss mit kurzem spike

- 55150 Verstellbare L-förmige Armatur mit langem, glattem spike

- 55160 45-mm-Anschlussstück mit kurzem, glattem spike

- 55175 Verstellbarer zylindrischer 45-Außengewindeanschluss

- 55180 Racor intermedio a 45

- 55216 Zentrales, zylindrisches, verstellbares T-Stück mit Außengewinde und O-Ring

- 55226 Verstellbares, zylindrisches, seitliches T-Stück mit Außengewinde und O-Ring

- 55230 T-Zwischenstück

- 55235 T-Stück mit Seitenadapter

- 55237 T-Stück mit Zentraladapter

- 55240 Verstellbares T-Stück mit kurzem, glattem spike

- 55310 Y-Zwischenstück

- 55315 Y-Zwischenstück mit Adapter

- 55320 Konischer männlicher verstellbarer Y-Anschluss (kurz)

- 55325 Verstellbarer zylindrischer Y-Stecker mit O-Ring

- 55330 Y-Verbindungsstück für Zwischenverteiler

- 55345 Verstellbarer Mehrfach-Y-Anschluss, zylindrisches Außengewinde mit O-Ring

- 55350 Reduzierstück für Mehrfachverteiler

- 55365 Zylindrisches, verstellbares Mehrfachverteiler-Reduzierstück mit Außengewinde und O-Ring

- 55500 einfach verstellbarer Ring

- 55510/5520 Doppelter verstellbarer Ring

- 55410 einfach

- 55420Doppelschraube

- 55430 Dreifachschraube

- 55440 einfach mit Außen- und Innengewinde

- 55620 Stecker

- 55625 Union

- 50700N/55700 Reduzierung

- 55705 Erweiterung

- 50900N 5- Wege -Aluminiumstreifen

- 56000 MINI-Serie

- 56010 Gerades zylindrisches Außengewinde mit Innensechskant-O-Ring

- 56020 Zylindrisches, gerades Außengewinde

- 56040 Mittlerer gerader Anschluss

- 56050 Zwischenschottverschraubung

- 56115 Zylindrischer, männlicher, verstellbarer L-Anschluss

- 56130 Zwischen-L-Anschlussstück

- 56215 Zylindrisches, zentrales, verstellbares T-Stück mit Außengewinde

- 56225 Zylindrisches, seitliches, verstellbares T-Stück mit Außengewinde

- 56230 T-Zwischenstück

- 56550 Verstellbarer Beschlag auf L

- 53000 FOOD-Serie

- 59000 FOOD-Serie

- 59020 Gerades zylindrisches Außengewinde mit O-Ring

- 59030 Gerades Anschlussstück mit Innengewinde

- 59040 Mittlerer gerader Anschluss

- 59100 Konischer L-Stecker mit Außengewinde

- 59116 Verstellbares L-förmiges zylindrisches Außengewinde mit O-Ring

- 59130 L-Zwischenstück

- 59216 Zentrales, zylindrisches, verstellbares T-Stück mit Außengewinde und O-Ring (FKM)

- 59216 Zylindrisches, seitliches, verstellbares T-Stück mit Außengewinde und O-Ring (FKM)

- 59230 T-Zwischenstück

- Zubehör der FOOD-Serie

- 70000-Serie

- 60000 INOX-Serie

- 60000 Konisches, gerades Außengewinde

- 60020 Gerades zylindrisches Außengewinde mit O-Ring (FKM)

- 60030 Gerades Anschlussstück mit Innengewinde

- 60040 Mittlerer gerader Anschluss

- 60050 Gerade Zwischenschottverschraubung

- 60110X Konischer, männlicher, verstellbarer L-Anschluss

- 60115X Konischer, männlicher, verstellbarer L-Anschluss mit O-Ring

- 60130X Zwischen-L-Anschlussstück

- 60210X Konisches, zentrales, verstellbares T-Stück mit Außengewinde

- 60215X Verstellbarer zentraler zylindrischer T-Stecker mit Außengewinde und O-Ring

- 60230X Zwischen-T-Anschlussstück

- 60310X Zwischen-Y-Anschlussstück

- 60600 Zylindrischer Außenadapter mit O-Ring (FKM)

- 60700 Reduzierung

- 62000 INOX-Serie

- 62000 Konisches Männchen

- 62020 Konischer Reduzierstopfen

- 62040 Konische Union männlich-weiblich

- 62080 Konische Reduzierung

- 62300 Manschette

- 62310 Manschette mit Innengewinde

- 62315 Zylindrischer Stecker mit Innensechskant mit O-Ring (FKM)

- 62320 Zylindrischer Stecker

- 62325 Konischer Stecker Innensechskant

- 62340 Konischer männlicher Zapfen

- 62355 Männlicher L-förmiger Zapfen

- 62360 Trennwanddurchführungsbeschlag

- 62400 T-Anschlussstück mit Innengewinde

- 62420 Zentrales T-Anschlussstück mit Innengewinde

- 62430 Seitliches T-Anschlussstück mit Innengewinde

- 62440 Zentrales männliches T-Stück

- 62450 Seitlicher T-Stecker mit Außengewinde

- 62500 L-Stecker, männlich

- 62510 L-Anschlussstück mit Innengewinde

- 62520 L-Anschluss männlich/weiblich

- 62540 Schalldämpfer aus EDELSTAHL

- 62600 Zentraler männlicher 90°-Y-Anschluss

- 62610 90° weiblicher Y-Abzweig

- 58000-Serie

- Zubehörserie

- Zubehör

- Schnellstecker

- Rohr und Spiralen

- Automatisierung

- Magnetventile für Flüssigkeiten

- Druckluftnetze (Infinity)

- Fittings

- Metal Work

- Aktuatoren

- Ventile

- Ventile

- Mechanisch-manuelle Betätigungs-Miniventile der Serie VME

- Pedalsteuerventile der PEV-Serie

- Zweihand-Sicherheitsventil der SAFE AIR-Serie

- Ventile der Serie 70

- Ventile der Serie 70 auf Sockel

- NAMUR-Ventile

- Ventile der BASIC-Serie

- Spulen und Anschlüsse für Ventile der Serie 70, NAMUR und BASIC

- Elektropneumatische ISO 5599/1-Ventile der ISV-Serie mit M12-Anschluss

- Prozessventile für mehrere Flüssigkeiten

- Ventile

- Filtergruppe

- Syntesi

- Syntesi Filter

- Syntesi Debugger

- Syntesi Aktivkohlefilter

- Regler Syntesi

- Syntesi-Batterieregler

- Pilotierbarer Regler Syntesi

- Syntesi Reglerfilter

- Syntesi Schmierstoffgeber

- Umschaltventil Syntesi Kreislauf

- Syntesi Druckschalter

- Syntesi Lufteinlass

- FR + LUB Syntesi

- V3V + FR + LUB Syntesi

- FIL + DEP Syntesi

- FIL + LUB Syntesi

- Syntesi Zubehör

- Syntesi Ersatzteile

- Bisschen

- Neuer Deal

- Präzise Regelung und präzise Steuerung

- Syntesi

- Fittings

- Automatische Fittings

- Automatische Messingverschraubung für Rohre in mm und G (BSP) oder metrisches Gewinde

- Zylindrisches gerades Außengewinde (R1)

- Gerades Innengewinde (R2)

- Mittlerer gerader Anschluss (R3)

- Zwischen-L-Anschluss (R4)

- Zwischen-T-Stück (R5)

- Gewindeadapteranschluss (R6)

- Erweiterter Gewindeadapter (R18)

- Verlängerungsbeschlag (R7)

- Reduzierstück (R8)

- Stecker (R9)

- Gerader durchführungen (R10)

- einfach Banjo-Verschraubung (R13)

- Doppelter Banjo-Anschluss (R14)

- Drehbares, einfach Banjo-Außengewinde (R15)

- Doppelte drehbare Banjo-Außenverschraubung (R16)

- Drehbares zylindrisches L-Außengewinde (R31)

- Drehbarer zentraler T-Anschluss mit zylindrischem Außengewinde (R32)

- Rotierendes zylindrisches seitliches T-Verbindungsstück mit Außengewinde (R38)

- Kreuzbeschlag (R40)

- einfach Hohlverschraubung mit 2 Drehkörpern (R50)

- Doppelhohlverschraubung mit 2 Drehkörpern (R51)

- einfach Hohlverschraubung mit 3 Drehkörpern (R52)

- Doppelhohlverschraubung mit 3 Drehkörpern (R53)

- Einstellbare einfach Banjo-Außenverschraubung (R54)

- Verstellbare Doppel-Außenverschraubung (R55)

- 2-Körper- einfach Banjo-Außenverschraubung, verstellbar (R56)

- Doppelte Banjo-Außenverschraubung, 2 verstellbare Körper (R57)

- Automatische Fittings aus Technopolymer für mm-Rohre und G- (BSP) oder metrische Gewinde

- Gerades Zwischenstück aus Technopolymer (R19)

- Technopolymer-Schwenkverschraubung einfach Banjo-Außengewinde (R20)

- Doppeldrehbare Banjo-Außenverschraubung aus Technopolymer (R20/A)

- L-Zwischenstück aus Technopolymer (R21)

- T-Zwischenstück aus Technopolymer (R22)

- Y-Anschlussstück aus Technopolymer (R23)

- Y-Anschlussstück aus Technopolymer (R23/M)

- Y-Anschluss mit Technopolymer-Adapter (R24)

- Seitlicher Y-Anschluss mit Außengewinde aus Technopolymer (R25)

- einfach Banjo-Verschraubung aus Technopolymer (R28)

- Doppelter Banjo-Anschluss aus Technopolymer (R29)

- Drehbarer L-Stecker aus Technopolymer (R34)

- Drehbares L-Innengewinde aus Technopolymer (R34/F)

- Zentraler T-Anschluss mit drehbarem Außengewinde aus Technopolymer (R35)

- Drehbares zentrales T-Verbindungsstück aus Technopolymer (R35/F)

- Verlängertes drehbares L-Außengewinde aus Technopolymer (R36)

- Verlängertes, drehbares, zentrales T-Verbindungsstück aus Technopolymer (R37)

- Doppel-Y-Anschlussstück aus Technopolymer (R42)

- Doppel-Y-Anschluss, Gewindeeingang aus Technopolymer (R43)

- Verteilerverschraubung aus Technopolymer (R44)

- Verteilerverschraubung, Gewindeeingang aus Technopolymer (R45)

- Schnellkupplungs-Winkelstück (R46)

- Erweiterter Schnellkupplungs-Winkelanschluss (R47)

- Zentrales Schnellkupplungs-T-Stück (R48)

- Seitliches Schnellkupplungs-T-Stück (R49)

- Automatische Messingverschraubung für Rohre in mm und G (BSP) oder metrisches Gewinde

- Fittings Serie A - Serie B - Serie C - Serie D

- Fittings der A-Serie

- Fittings der C-Serie

- Konisches, gerades Außengewinde (C1)

- Gerader männlicher Zylinderanschluss (C1/Z)

- Gerades zylindrisches Außengewinde ohne OR (C1/C)

- Gerades Anschlussstück (C2)

- Mittlerer gerader Anschluss (C3)

- Gerader durchführungen (C4)

- Konisches männliches L-Fitting (C5)

- Weibliches L-Anschlussstück (C5/F)

- Zylindrisches L-Außengewinde (C5/C)

- Zwischen-L-Anschlussstück (C6)

- T-Stück, konisches Außengewinde (C7)

- T-Anschluss, konisches Außengewinde (C8)

- Zwischen-T-Stück (C9)

- Mutter (C10)

- Kreuzbeschlag (C11)

- Fittings der D-Serie

- Automatische Fittings

- Zubehör

- Top Cable

- Sicomat